The manufacture of custom footwear involves several important aspects to consider.

Here are some key points to keep in mind:

Material selection:

Selecting appropriate materials holds significant importance. This encompasses materials for the upper part, the lining, as well as the outsole, and so on. Make certain that these materials adhere to quality criteria and offer the necessary comfort, long-lasting performance, and practical functionality.

Production processes:

Establishing an appropriate production process is vital to ensure that every step of footwear production is strictly controlled and inspected. This includes cutting, stitching, bonding, assembly, and packaging.

Quality control:

Strict quality control is necessary throughout the manufacturing process. This includes quality checks on raw materials, inspections and testing during production, and final inspection of the finished product.

Size and compatibility:

Make certain that the shoe sizing and its compatibility align with what the target market anticipates. This involves carrying out tests on various shoe sizes and implementing modifications whenever necessary.

Comfort and functionality:

Ensure that the footwear provides adequate comfort and functionality. This may involve the design and selection of insoles, outsoles, and other functional requirements such as waterproofing and slip resistance.

Environmental sustainability:

Consumers are increasingly concerned about environmental sustainability. When making shoes, it’s important to consider using eco-friendly materials, reducing waste and energy consumption, and adopting sustainable production methods.

Design strength

Design trends:

Footwear design trends are constantly changing, and manufacturers need to closely follow the latest market trends and consumer preferences. This includes color, style, pattern, and material trends to ensure that custom footwear meets market demands and appeals to consumers.

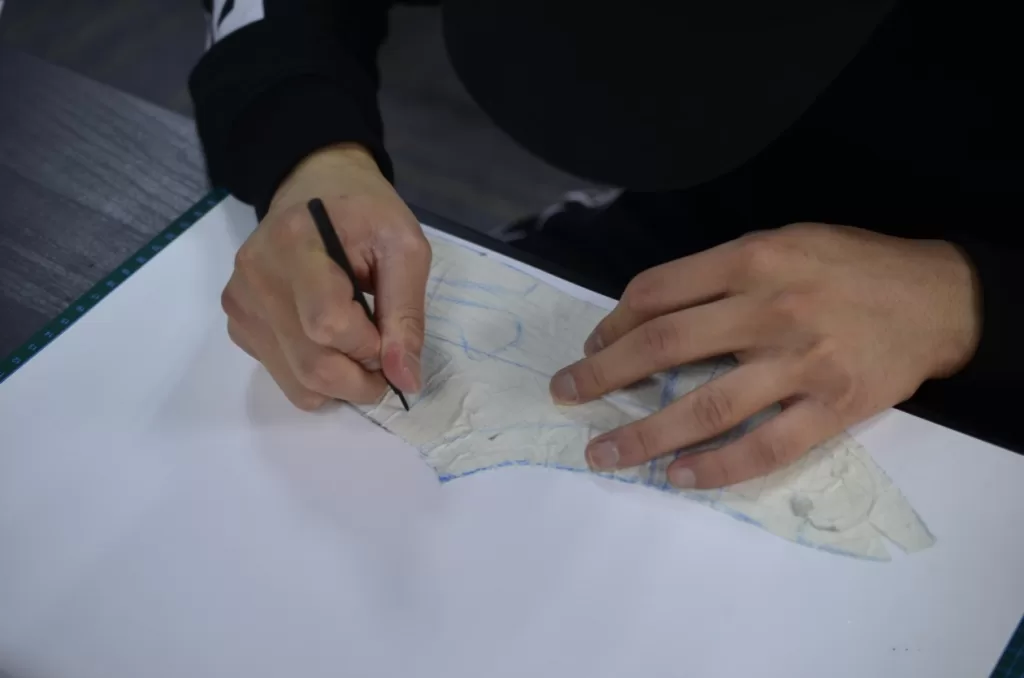

Design and prototyping:

First make sure the designer’s drawings and prototypes meet your requirements. The prototype should be viable for actual production in order to continue the manufacturing process.

Design, material selection, production process, quality control, fit size, comfort functionality, environmental sustainability and design trends are all crucial considerations in the manufacturing of custom footwear. Therefore, customized shoes to meet the individual needs of consumers at the same time, but also to buyers to show the strength of the company.