Vulcanized shoes are favored by young consumers becaused of their classic shoe style.Their production process combines traditional craftmanship with modern technology.This preserves the classic style of the shoe while improving its comfort and durability. Next, let us take a look at their entire production process.

Select materials of vulcanized shoes

The creation of these shoes begins with the selection of materials. The uppers are mostly made of canvas, leather and other materials with good breathability and unique texture. And the outsole usually uses processed rubber material. Next is the production of the uppers and soles. Designers will cut and sew selected materials according to the shoe style. This process requires precise calculation of dimensions to ensure a perfect fit between the upper and the sole. At the same time, the choice of suture is also crucial. It will directly affect the beauty and durability of the shoes.

Vulcanization procedure

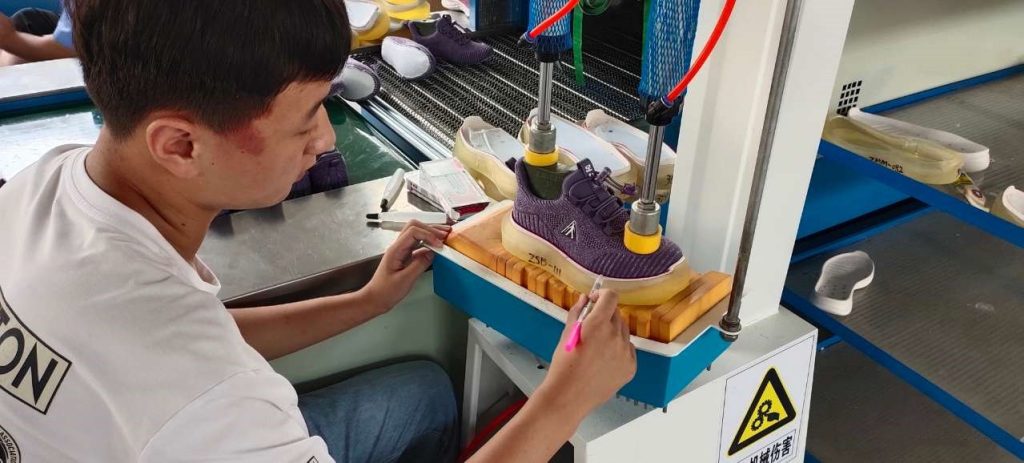

The production of soles is the most important step in the entire production process. Traditional rubber materials will become hard and brittle in low temperature weather, and will easily melt and crack when the temperature is high. On the contrary, vulcanized rubber products are not easy to age and crack, are heat-resistant and have good elasticity. Therefore, most of today’s canvas shoes choose this vulcanization treatment method. By heating and pressurizing, the sulfur element in the rubber material reacts with the rubber molecular chain. The vulcanized soles not only have better hardness and wear resistance, but also maintain elasticity for a long time. The final step is to combine the upper with the sole. And that usually uses a vulcanizer to tightly fit the two parts and vulcanize them at high temperatures. The finished shoes need to be cooled, trimmed, and polished to ensure their beauty.

The production process of vulcanized shoes seems simple, but every step needs to be strictly controlled. It is the careful handling of every detail that enables footwear to remain in the fashion market for a long time.