Shoemaking is a meticulous process that involves a series of intricate steps to create footwear that combines functionality and aesthetics. In this exploration we will delve into the five main processes that bring a pair of shoes from raw materials to a finished product. From the widely used gluing process to the traditional sewing process, each step contributes to the unique qualities of the final footwear.

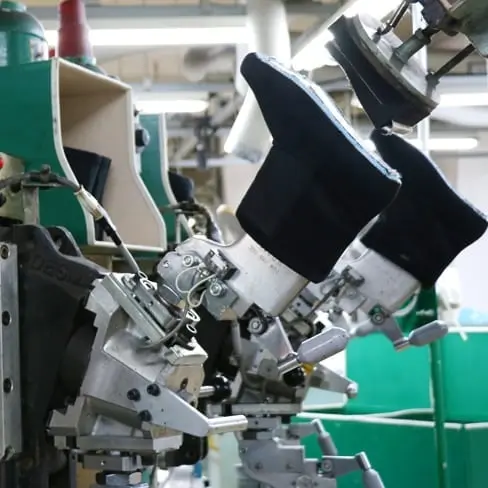

The Gluing Process

The gluing process stands as a cornerstone in modern making progress, widely adopted for its adaptability and efficiency in assembly line operations. This method is suitable for various materials, offering versatility in design. Let us take adhesive shoes as an example. The process involves fabric and lining cutting, bottom making with various shaping techniques. Next, closing the bottom by combining the upper and bottom, followed by drying, shaping, and the crucial step of exiting the last. The final phase includes meticulous inspection to ensure quality standards.

Hot Vulcanization shoemaking Process

Divided into the hot vulcanization paste and molding processes. Hot vulcanization plays a pivotal role in the production of rubber-soled footwear like travel shoes and sports casual shoes. The main steps in the hot vulcanization paste process include the manufacture of uppers and glue parts, molding, vulcanization, and last removal. Besides, this method ensures the durability and resilience of rubber soles, making them ideal for various demanding environments.

Injection Molding shoemaking Process

Utilized primarily in travel shoes, sports shoes, and sports casual shoes, injection molding is a method that offers precision and versatility. It involves the compression and plasticization of materials in an injection molding device. Furthermore, it is followed by the injection of fluid plastic into the shoe cavity through the mold’s injection channel. The process further differentiates into whole shoe injection molding and sole injection molding, with variations such as single-color and multi-color injection molding.

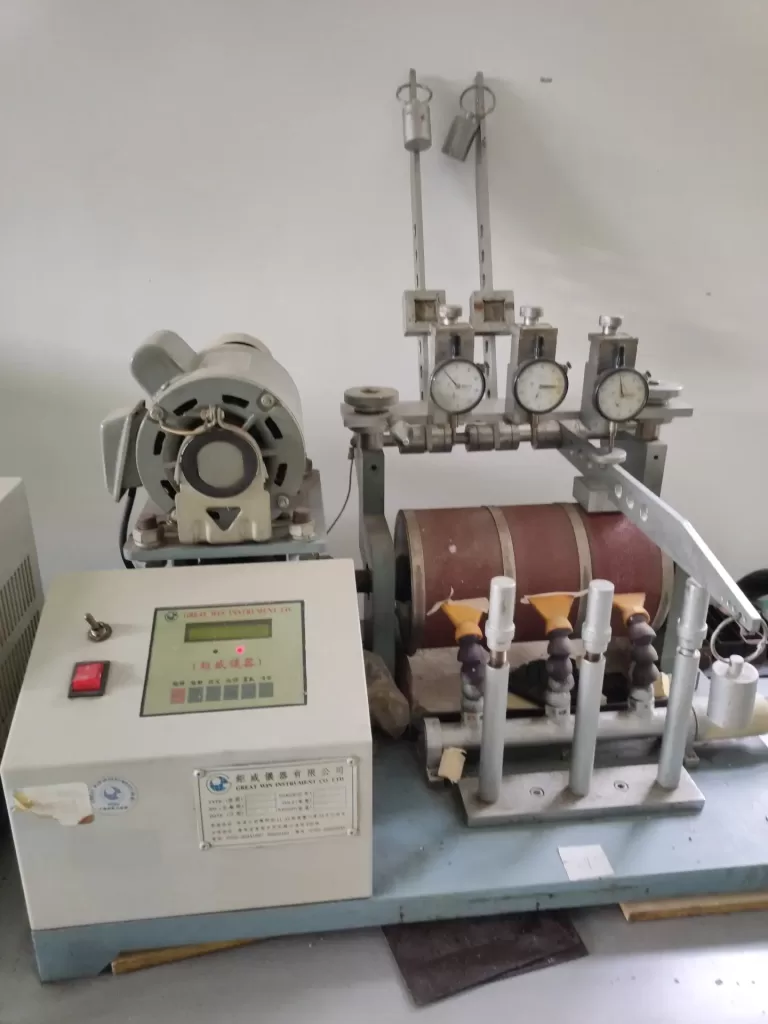

Molding Process

The molding process finds its niche in footwear requiring high binding strength between the upper and bottom, such as labor protection shoes and military footwear. The two main types of molding processes, stretch molding and last molding, involve intricate steps like raising the upper, applying adhesive, and pressing the rubber material onto the bottom mold using a molding machine. This results in a tightly synthesized product, showcasing the craftsmanship and attention to detail essential in the creation of specialized footwear.

Sewing Process

A traditional and intricate method, the sewing process adds a touch of artistry to shoemaking. This technique involves sewing the combination of the upper and bottom with special hemp threads. While complex and demanding, the sewing process is reserved for high-end leather shoes, where the emphasis is not only on processing and molding materials but also on the exquisite, perfect, and complex craftsmanship. This meticulous approach brings forth a sense of craftsmanship and aesthetic value appreciated by discerning consumers.

In conclusion, the art of shoemaking involves a symphony of processes, each contributing to the final masterpiece. From the efficiency of gluing to the resilience of hot vulcanization, the precision of injection molding, the strength of molding, and the artistry of sewing, these processes collectively shape the diverse landscape of footwear, meeting the demands of both functionality and aesthetics.